EKAE... / EKAD... - Duct fans with forward curved centrifugal impellers

- easy installation (DIN standard flange)

- can be installed in any position

- extremely low starting current

- motor protection by thermal contacts

- speed is variable using auto transformers

_____________________________________________________________________________________________________

Description:

The Rosenberg duct fans provide a distinctive advantage of axial fans, i.e. straight airflow and easy installation, high pressure stability, low noise level and high efficiency of the centrifugal fan.

Application areas:

Garage / Offices / Bars / Greenhouses / Skyscrapers / Hotels / Industrial buildings / Basement rooms / Playschool / Cinemas / Parking facilities / Warehouses / Nursing homes / Schools / Sports halls / Supermarkets / Workshops / Residential houses / Fitness centers / Inflatables

Reference to Directives:

Declaration of incorporation and operating instruction are according to Machinery Directive 2006/42/EC, CE identification in accordance to EMC-Directive 2014/30/EU, Low Voltage Directive 2014/35/EU and the Ecodesign-Directive 2009/125/EC.

_____________________________________________________________________________________________________

Casing:

Casings are made of galvanized sheet steel, formed as a rectangular duct for direct installation into air ducts. Mounting possible in any position. Standard flanges are installed on inlet and outlet side. This allows simple and quick connection to the duct section. Optional flexible connectors and flange are available. The complete motor impeller unit can be easily detached for cleaning.

_____________________________________________________________________________________________________

Impellers:

The forward curved impellers are directly mounted to the rotor of the external rotor motor and are balanced dynamically together with rotor according to quality level G2.5 to DIN1940.

Size EKAE 200-2

backward curved centrifugal impeller made of plastic

From size EKA 200-4

forward curved centrifugal impeller made of galvanized sheet steel

_____________________________________________________________________________________________________

Motor and motor protection:

All Rosenberg fans are equipped with direct driven external rotor motors. All our fans have motor protection through thermal contacts in the motor windings as standard. The motors apply to protection class IP44/IP54.

Size EKAE 200-2 = motor protection class IP44

From size EKA 200-4 = motor protection class IP54

The drive has due to an external rotor motor a space saving, compact and attractive design. The motor is fitted within the impeller, which enables the best possible cooling. For this reason a 100% variable speed control can be guaranteed. V-belts, additional tension bars and motor mounting devices are not necessary. Only well-dimensions ball-bearings, fitted on both sides and life time greased are used.

Both ball-bearing seats are ground to high precision in one work process to eliminate any vibrations.

External rotor motors have extremely low starting currents. The windings comply to isolation class F.

In addition the windings have a standard moisture impregnation.

_____________________________________________________________________________________________________

Electrical connection:

The motors are fitted with an outgoing cable. The electrical connection can be made via an IP44 terminal box, which is supplied loose.

Direction of rotation

Direction of rotation is clockwise, viewed from the inlet side.

_____________________________________________________________________________________________________

Installation:

The duct fans are mounted with the desired accessory (duct silencer, filterbox, etc) in the ductwork.

To avoid possible vibration onto the channel system, we recommend the use of flexible connections (optional).

_____________________________________________________________________________________________________

Air volume control:

For more information see accessories!

5-speed control unit:

230V à RTE …

400V à RTD …

Infinitely variable control unit:

230V à ED / REE …

400V à RED …

400V à Frequency converter / WARNING: up to max. 50Hz

2-speed control unit:

400V à MSD 2

_____________________________________________________________________________________________________

Scope of delivery:

· Duct fan (EKAE / EKAD)

· Terminal box (loose)

· Documentation

_____________________________________________________________________________________________________

Important notes:

Air performance curves:

The performance curves for these fan types have been measured in mounting position D (installed on the pressure side and open on the suction side) and show the total pressure increase ∆pt as a function of the air flow. The dynamic pressure ∆pd2 refers to the flange cross section at the outlet side of the fan.

Noise levels:

The bordered values printed in the performance curve diagrams show the "A" weighted LWA6 sound power level at the outlet side in duct systems. The relative octave sound power level LWArel at octave medium frequency you can find on type page.

Classification of the fan series:

NRVU = Non Residential Ventilation Units

UVU = Unidirectional Ventilation Units

Erp-Information:

Rosenberg fans have a spezfic (pressure-) ratio < 1,05 (pressure < 5000 Pa).

Service life:

For maximum service life of Rosenberg products please beware of the maintenance hints on the manual for each product type.

Recycling and disposal:

For recycling and disposal of Rosenberg products comply with applicable locally requirements and regulations.

EKAE 200-2: Duct fan with backward curved impellers

Casings are made of galvanized sheet steel, formed as a rectangular duct for direct installation into air ducts. Mounting possible in any position. Standard flanges are installed on inlet and outlet side. This allows simple and quick connection to the duct section.

The backward curved impellers are directly mounted to the rotor of the external rotor motor and are balanced dynamically together with rotor according to quality level G2.5 to DIN1940. The impellers made of plastic.

The drive has due to an external rotor motor a space saving, compact and attractive design. The motor is fitted within the impeller, which enables the best possible cooling. For this reason a 100% variable speed control can be guaranteed. V-belts, additional tension bars and motor mounting devices are not necessary. Only well-dimensions ball-bearings, fitted on both sides and life time greased are used. Both ball-bearing seats are ground to high precision in one work process to eliminate any vibrations. External rotor motors have extremely low starting currents. The windings comply to isolation class F. In addition the windings have a standard moisture impregnation.

Documentation:

Declaration of incorporation and operating instruction are according to Machinery Directive 2006/42/EC, CE identification in accordance to EMC-directive 2004/108/EC and Low Voltage Directive 2006/95/EC. Motor operating instruction is available from motor manufacturer.

From EKAE 200-4 to EKAE 315-6 K: Duct fans with forward curved impellers

Casings are made of galvanized sheet steel, formed as a rectangular duct for direct installation into air ducts. Mounting possible in any position. Standard flanges are installed on inlet and outlet side. This allows simple and quick connection to the duct section.

The forward curved impellers are directly mounted to the rotor of the external rotor motor and are balanced dynamically together with rotor according to quality level G2.5 to DIN1940. The impellers made of galvanized sheet steel.

The drive has due to an external rotor motor a space saving, compact and attractive design. The motor is fitted within the impeller, which enables the best possible cooling. For this reason a 100% variable speed control can be guaranteed. V-belts, additional tension bars and motor mounting devices are not necessary. Only well-dimensions ball-bearings, fitted on both sides and life time greased are used. Both ball-bearing seats are ground to high precision in one work process to eliminate any vibrations. External rotor motors have extremely low starting currents. The windings comply to isolation class F. In addition the windings have a standard moisture impregnation.

Reference to Directives:

Declaration of incorporation and operating instruction are according to Machinery Directive 2006/42/EC, CE identification in accordance to EMC-Directive 2014/30/EU, Low Voltage Directive 2014/35/EU and the Ecodesign-Directive 2009/125/EC.

For further information, please click the model below for detail.

| EKAE 200-2 | EKAE 250-4 | EKAE 280-4 |

| EKAE 200-4 | EKAE 250-4.5FA | EKAE 280-4.6FA |

| EKAE 225-4 K | EKAE 250-6 | EKAE 280-6 K |

| EKAE 225-4 | EKAE 315-6 K |

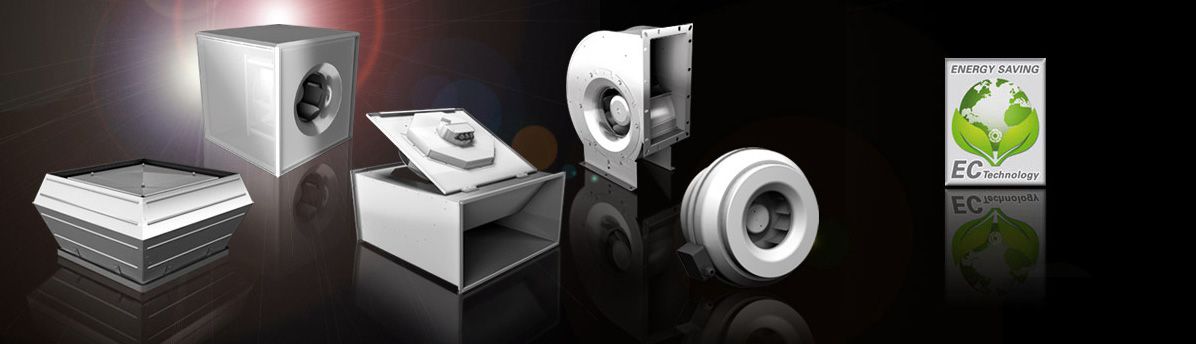

Picture of duct fans AKAE

1.jpg)