Application for Bifurcated Fans Rosenberg

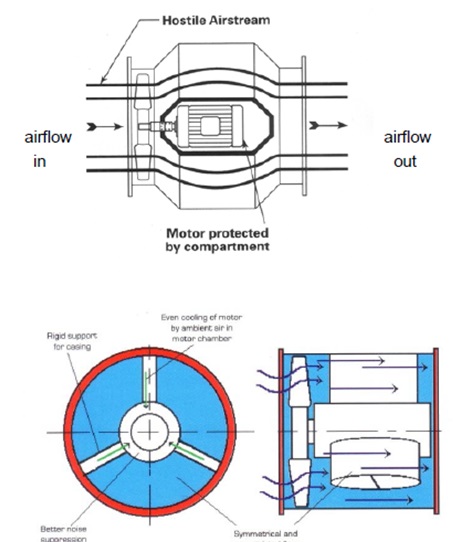

Bifurcated fan design is generally similar to a normal axial flow fan that has been develop to handle wet or dirty atmospheres, hot gases or dust laden air. The fan is designed with a split airway and the motor is protected from the handled air by having its own compartment.

The motor is isolated from the main air stream by a tunnel which extends to the side of the main fan casing. The motor is cooled by air directly flowing over its carcass by means of a cooling fan mounted on the shaft extension at its tail end.

The Bifurcated fan is suitable for some mild chemicals that will not corrode the galvanised casing or the seal of the motor shaft through the case. Additional protection can be provided by an epoxy paint finish.

Bifurcated fan when fitted with an anti- spark track can also be use to handle hazardous gases. However, the fan must be mounted outside the hazardous area.

Air Working Temperature for Bifurcated Fans Rosenberg

As a standard, our bifurcated fan is fitted with a class H insulation motor and is suitable for operation in air temperature up to 2000C.

The motor is cooled by ambient air drawn into the tunnel which extends to the side of the casing and should be used in maximum 400C ambient temperature. Means of extra cooling of the motor must be allowed for higher ambient temperature.

Motor with Class F insulation can also be installed. However, the maximum air temperature will only be 1500C.

Casings for Bifurcated Fans Rosenberg

The casing after fully manufactured from mild steel will be hot dipped galvanised as an anti corrosive measures and for longer life span. Every casing comes with defined flange master gauge for holes to ensure an easy connection to the duct system.

The casing of the 315 to 500mm diameter sizes have an enlarged bore located around the motor to permit adequate cross sectional area for air to flow round the motor tunnel. 560 to 1400mm diameter fan have casings of constant diameter.

Impeller for Bifurcated Fans Rosenberg

The axial impellers are balanced on quality level G 6.3 according to DIN ISO 1940. The hubs of chilled casting aluminum are made in two parts and have removal drilling for easy dismounting of the impellers. The profile blades are also made of aluminum with adjustable pitch angles.

Motors for Bifurcated Fans Rosenberg

TEFC , 3 phase IEC motors of type B3 or B5 with IP55, insulation class H or F are used. Motor used complies to IEC 60034 standard. Motor with IE1 efficiency are used as a standard. Higher efficiency such as IE2, IE3, dual speed motor and explosion proof motors are also available upon requested.

Performance for Bifurcated Fans Rosenberg

Performance curves and technical specifications are based upon tests in accordance with AMCA 210-99 standard. Test results are corrected to standard air density of 1.2kg/m3 at a temperature of 200C. Sound level data should be used as a guide only, as the site junctions, directivity, absorption, method of mounting, duct junctions and reflectiveness of adjacent surfaces can all combine to influence what the

resultant overall noise level will be. Sound spectrum data's are available on request.

Standard for Bifurcated Fans Rosenberg

The fan casing and accessories(optional items) are all hot dipped galvanised after manufacture.

Self finished or painted motor are in accordance to motor manufacturers specification.

Extra Features for Bifurcated Fans Rosenberg

· Treated with an epoxy paint finished at extra cost.

· Stainless steel construction

· Explosion proof motor with anti-spark feature.

· Non standard voltages.

· Motor anti-condensation heaters and thermistors.

The contact addresses are to be found in the attachment, or else please phone +49 (0)7940 / 0917 186 894 or email to info@rosenberg.com.vn